Trim Saw vs. Slab Saw

If you’re new to lapidary, you might be wondering what the difference is between a trim saw and a slab saw. Both types of saws are used to cut rocks, minerals, and other materials, but they have some key differences that make them better suited for different tasks. In this article, we’ll explore the differences between trim saws and slab saws, including their features, uses, and advantages.

Related: Where To Find Used Lapidary Equipment

Trim Saws

Trim saws are small, lightweight saws that are used to cut thin slices or “trims” off of rocks, minerals, and other materials. They typically have a circular blade that is 6 inches or less in diameter and are powered by a motor. Trim saws are designed for precision cutting and are often used to cut thin slices of material for cabochons, beads, or other jewelry.

Trim saws have a number of features that make them well-suited for precision cutting. For example, many trim saws have adjustable blade guides that allow you to set the depth of the cut, which can be useful when cutting thin slices or shapes. They also usually have a clear plastic hood or cover that helps to keep debris and dust contained while you’re cutting. Trim saws are also often times cooled with just water.

Trim saws are a good choice for beginners or those who are working with small, thin slices of material. They are relatively easy to use and don’t require a lot of setup or maintenance. However, they are not well-suited for cutting thicker or larger pieces of material, as the small blade is typically unable to handle the load of larger rock specimens.

Slab Saws

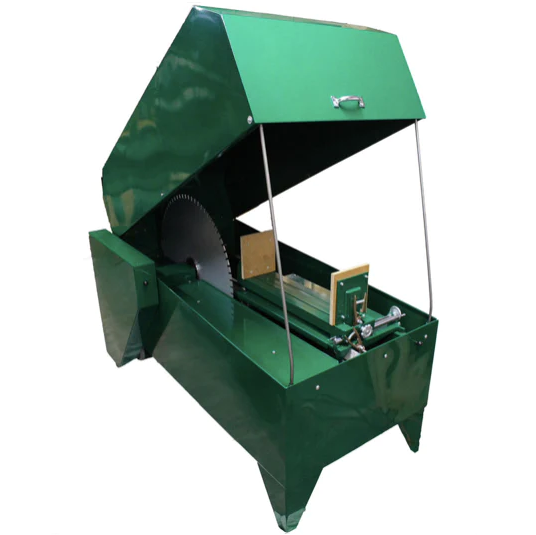

Slab saws are larger, more powerful saws that are used to cut thicker, larger pieces of material. They typically have a large blade that is 12 inches or more in diameter and are powered by a motor. Slab saws are used to cut rough slabs of material, which can then be trimmed, polished, or shaped with other lapidary tools.

Slab saws have a number of features that make them well-suited for cutting thicker, larger pieces of material. For example, many slab saws have adjustable blade guides that allow you to set the depth of the cut, which can be useful when cutting slabs of different thicknesses. They also usually have a large table or work surface that provides plenty of room to maneuver the material while you’re cutting. Slab saws are also often times cooled with the use of oil.

Slab saws are a good choice for those who are working with thicker or larger pieces of material. They’re more powerful than trim saws and can handle the load of cutting through thicker slabs. However, they are generally not as precise as trim saws and may produce rougher or less accurate cuts. Slab saws also typically require more setup and maintenance than trim saws.

Related: How To Cut Rocks With a Tile Saw

Differences in Blade Size

One of the main differences between trim saws and slab saws is the size of the blade they use. Trim saws typically have small, thin blades. These blades are typically 4″ to 6″ in diameter and run between .004″ and .012″ thick. Trim saws are designed for precision cutting and are often used to cut thin slices of material for cabochons, beads, or other jewelry.

On the other hand, slab saw blades are thicker because they are designed to do much heavier cutting. These blades run from 6″ to 36″ in diameter and have a thickness of .025″ to .200″. Slab saws are used to cut rough slabs of material, which can then be trimmed, polished, or shaped with other lapidary tools.

Differences in Lubrication Requirements

One important aspect to consider when using lapidary saws is the lubrication requirements. Trim saws will last and work well without any lubrication other than water. And this is exactly what many lapidaries use. However, water alone is not 100% recommended. At the minimum, you should consider adding a rust preventative that usually has lubricating properties as well.

On the other hand, slab saws have much more stringent requirements when it comes to lubrication. There are saw oils on the market that are excellent but expensive. If you’re unsure what to use, it’s best to get an oil that is specifically designed for lapidary use. This will ensure that your slab saw is properly lubricated and running smoothly.

Final Thoughts

Trim saws and slab saws are both useful tools in the lapidary workshop, but they are designed for different tasks. Trim saws are best suited for precision cutting of thin slices of material, while slab saws are better for cutting thicker, larger pieces of material. Depending on your needs and the type of material you’re working with, you may need to use both types of saws in your lapidary work.

- Online rock and mineral club for collectors of all levels!

- Find community with like-minded rock and mineral enthusiasts.

- Monthly Giveaways!

- Free Access to Entire Digital Library of Products (current and future products)*